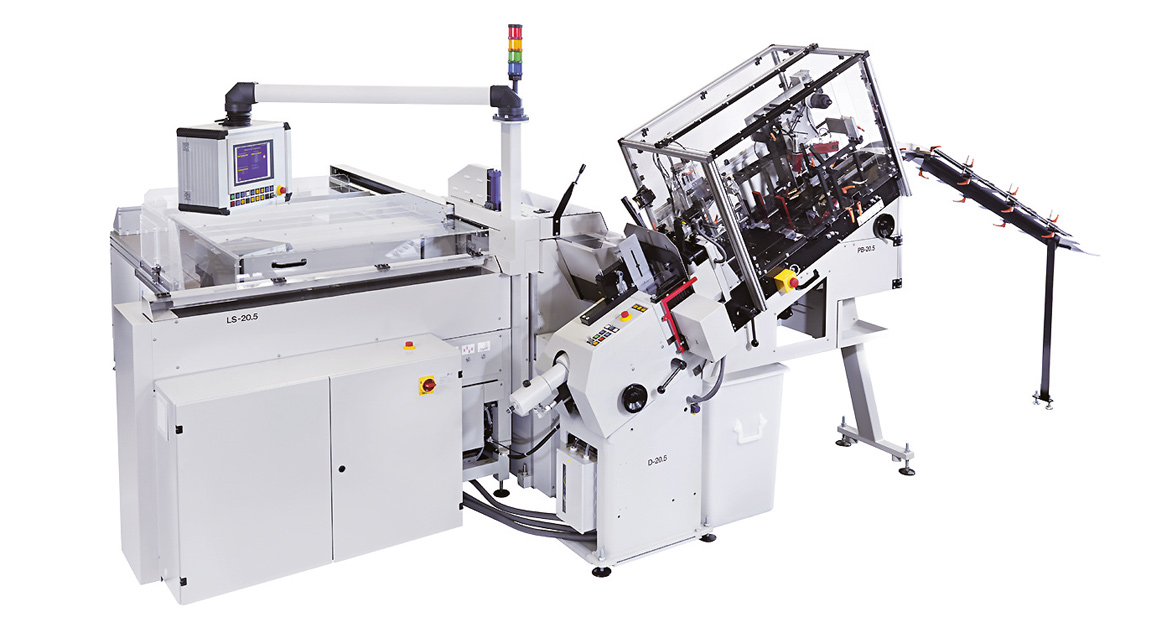

Together with our customers all over the world, we have been creating variety, quality and efficiency in the post-print industry. Our core products are complex cutting, die-cutting and banding machines and lines for the production of customised labels and credit cards.

Systems & Machines

There is a reason why Blumer systems are held in high esteem all over the world. It’s because of Blumer’s boundless commitment to research and development, the positive attitude toward knowledge transfer, the alliance of people with a wealth of know-how in the different areas.

detailsServices

For us, customer service begins with a deep understanding of our customers’ needs. We help you professionally, straightforwardly and quickly.

details

DE

DE